-

Componenti ceramiche dell'allumina

-

Alloggio ceramico

-

Ceramica metallizzata dell'allumina

-

Parti in ceramica personalizzate

-

Isolante ceramico dell'allumina

-

Anelli ceramici dell'allumina

-

Sensore di pressione ceramico

-

Ceramica tecnica avanzata

-

Ceramica di ingegneria avanzata

-

Fonda ceramico

-

Blocchetti di connettore ceramici

-

Componenti ceramiche elettroniche

-

Magnetron ceramico

-

Parti ceramiche di biossido di zirconio

-

Allumina Rohi ceramici

-

Mr.FarnRisponda molto veloce e facile parlare!

Mr.FarnRisponda molto veloce e facile parlare! -

Mr.JacksonBuon servizio e piacevole per parlare.

Mr.JacksonBuon servizio e piacevole per parlare.

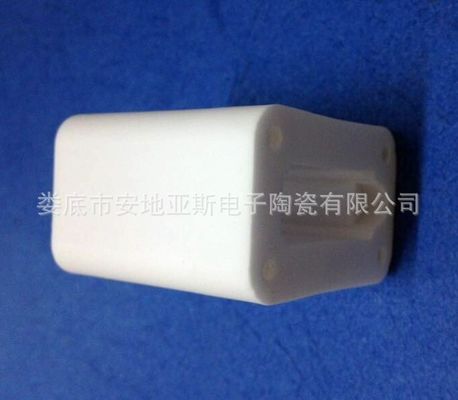

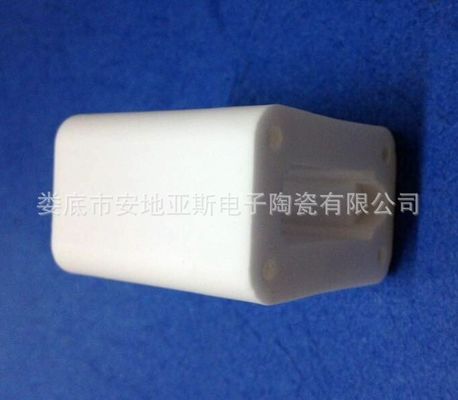

Alumina Ceramic Shell with Thermal Expansion Coefficient 8.2 X 10^-6 /K and Maximum Use Temperature 1600-1650℃ for High Bulk Density 3.6g/cm3-3.9g/cm3

Contattami per campioni e coupon gratuiti.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

In caso di dubbi, forniamo assistenza online 24 ore su 24.

x| Thermal Expansion Coefficient | 8.2 X 10^-6 /K | Flexural Strength | 200-400 MPa |

|---|---|---|---|

| Maximum Use Temperature | 1600-1650℃ | Hardness | 9 On Mohs Scale |

| Form | Solid | Usage | Ceramic Chamber DC Contactor Assembly |

| Bulk Density | 3.6g/cm3-3.9g/cm3 | Dielectricity Constant | 9-9.7 / 1MHz.25℃ |

| Evidenziare | Thermal Expansion Coefficient Alumina Ceramic Shell,Maximum Use Temperature Alumina Ceramic Shell,Bulk Density Alumina Ceramic Shell |

||

Product Description:

Alumina Ceramic Components are renowned for their exceptional quality and versatility, making them the ideal choice for various industrial applications. These components are known for their remarkable surface finish, with a polished exterior that enhances both aesthetic appeal and functionality.

One of the key attributes of Alumina Ceramic Components is their impressive RoHS hardness rating of equal to or greater than 85. This level of hardness ensures durability and longevity, making these components a reliable and cost-effective solution for a wide range of applications.

Moreover, Alumina Ceramic Components exhibit a high dielectric constant, typically ranging between 9 and 9.7 at 1MHz and 25°C. This excellent dielectric property makes these components ideal for use in electrical insulation applications, ensuring reliable performance and safety.

Another standout feature of Alumina Ceramic Components is their impressive breakdown voltage of 20 KV/mm. This high breakdown voltage ensures robust electrical insulation, making these components suitable for high-voltage applications where safety and reliability are paramount.

Furthermore, Alumina Ceramic Components are known for their exceptional gas tightness, with a leakage rate of less than or equal to 1.0 x 10^-11. This high level of gas tightness ensures that these components maintain their integrity in challenging environments, making them suitable for critical applications that require precise control of gas flow.

Whether you need Alumina Ceramic Pads, Alumina Ceramic Plates, or Alumina Ceramic Cases, these components offer superior performance and reliability across various industrial and commercial applications. Their polished surface finish, high RoHS hardness, excellent dielectric properties, impressive breakdown voltage, and exceptional gas tightness make them the preferred choice for demanding applications where quality and performance are non-negotiable.

Features:

- Product Name: Alumina Ceramic Components

- Surface Finish: Polished

- Flexural Strength: 200-400 MPa

- Breakdown Voltage: 20 KV/mm

- Rohs Hardness: ≥85

- Form: Solid

Technical Parameters:

| Thermal Expansion Coefficient | 8.2 X 10^-6 /K |

| Flexural Strength | 200-400 MPa |

| Gas Tightness | ≤1.0*10^-11 |

| Rohs Hardness | ≥85 |

| Package | Carton |

| Breakdown Voltage | 20 KV/mm |

| Surface Finish | Polished |

| Usage | Ceramic Chamber DC Contactor Assembly |

| Maximum Use Temperature | 1600-1650℃ |

| Dielectric Constant | 9.6 |

Applications:

Alumina Ceramic Components from the Antaeus brand, originating from Hunan, China, are versatile products suitable for a variety of application occasions and scenarios. The product attributes make it ideal for use in demanding environments where high performance and reliability are essential.

The Alumina Ceramic Cases are perfect for applications requiring a high level of hardness, scoring an impressive 9 on the Mohs scale. This makes them suitable for use in industries such as aerospace, defense, and electronics where durability is crucial.

Alumina Ceramic Shells are well-suited for applications where thermal stability is key. With a low thermal expansion coefficient of 8.2 x 10^-6 /K, these components excel in environments with fluctuating temperatures, such as in automotive engine components or semiconductor processing.

For applications where excellent electrical insulation properties are required, Alumina Ceramic Pads are the ideal choice. The gas tightness of ≤1.0*10^-11 ensures reliable performance in high-pressure or vacuum environments, making them suitable for use in medical devices, sensors, and high-tech equipment.

With a minimum order quantity and pricing open for negotiation, coupled with full supply availability, customers have the flexibility to meet their specific requirements. The delivery time of 15-45 days ensures timely fulfillment of orders, while payment terms can be settled through T/T or negotiation.

Each component is meticulously packaged for protection, with inner vacuum packaging and outer cartons ensuring safe transportation. The solid form and sturdy carton packaging further safeguard the components during transit, guaranteeing they arrive in pristine condition for immediate use.